Scan the QR

to read the magazine on mobile phone

Editor's Note:

Scheidle Joerg has more than 20 years of experience in the life sciences industry. As Executive Chairman of Luye Pharma AG, he is primarily responsible for the Luye Pharma plant in Germany. Prior to joining Luye in 2008, Joerg was CFO at Immatics Biotechnologies, a clinical stage immune-oncology biotech company. He started his career at BrainLAB, where he held a variety of positions in marketing and finance and helped drive the company’s rapid growth. He likes to play basketball and spend time with his family in his spare time and has a passion for historic cars.

Rivastigmine single-day patch is Luye Pharma’s first patch product in China and was developed by Luye Pharma AG on its proprietary transdermal patch platform. This product has successfully received market approval by National Medical Products Administration in China with the joint efforts of multiple departments across China and Europe. As one of the leaders of this international project, Joerg is invited for our December issue to share his experience with this project.

Joerg at the 25th anniversary celebration in Yantai

Q:Hi Joerg, long time no see. Thank you very much for taking your time for this interview. Please briefly introduce about the progress of the project and major achievement so far.

Joerg:I think if you go through it chronologically, the first and most important achievement was to receive the approval. This case is very specific because it's not the China organization that holds the MA but the German organization.

That's definitely something new to us and brought some extra complexity to the overall project. But I think the team managed and adapted well to those circumstances over time. The second milestone was that with the approval, there was a string attached. There was a certain extra requirement on analytics that the Chinese FDA required for the API manufacturer. Of course, the biggest milestone was that we eventually manufactured and delivered the product into China.

A lot of firsts happened in this setup. The team was agile enough to adapt to those new requirements. And I think the overall accomplishment is that we have overcome all those question marks along the way. We overcame those administrative and regulatory hurdles, and that’s fantastic.

Q: As we know, this is the first Luye patch product developed in Europe and marketed in China. Despite of the COVID-19 pandemic, we are still glad to see that it can went on time. Can you talk about some biggest challenges and solutions? Maybe some stories or examples?

Joerg: Preparing for the shipment has brought some extra challenge. With the overall transportation systems, especially air transportation, being at a record low level, and many planes that would have transported passengers and freight in the past are just not operating during the COVID time. It was obviously for the teams in Europe and China hard to find the right spots on the aircraft carriers.

Also, to identify the right container type for temperature control and aircraft fit turned out to be more challenging than in normal times. Obviously, this took the Supply Chain team some extra efforts, but they are all experts in their field and managed. We needed to be sensitive about these circumstances and then drew the plan ahead, instead of being confronted with the constraints that you cannot handle short term. I am convinced that's why it went smoothly.

Q:What is your take away from this project?

Joerg:I think the biggest take away is: if you've done it once, you can do it more often. The second time will be much easier. So that means follow up deliveries for Rivastigmine, but hopefully we will also have other patch products following the rivastigmine project in mid-term future.

Q:And the next one is about the teamwork. How do you think about the team work, especially for this kind of international project? How do you define the role of teamwork to the success completion of this project?

Joerg: Overall it would not have succeeded without teamwork. Remotely from Germany, would not have had a chance to provide all the documentation that was necessary for the registration, if it wasn't for the Chinese colleagues to define exactly what they need. Their highly valuable work as an interpreter between the local requirements and translation into language that our colleagues would understand was detrimental to the success. There is probably a cultural difference in terms of working methods and I think all in all the team learned on both sides over time. And that is part of what makes teamwork so important when looking at what needed to be accomplished. No matter how far the physical distance, or the cultural difference, within the project, you start linking those special requirements.

Project team prepared 84 document packages for market approval application

That's what we have seen not only on the regulatory challenge, but also, we needed to create a set of five different contracts intra company, just to make sure that all roles and responsibilities are clear between the different legal entities involved. It took more than a year to fully understand the complexity of the situation and to make sure that not only the operational departments, but also the legal departments are involved on both ends. All in all, also this work stream was accomplished on time.

Project team members from China and Germany

Q: Since you have mentioned, can you give us an example to show us what you have learned from this project in relate to the culture barriers or culture communication, considering this project needs synergies and team efforts among multiple departments including R & D, manufacturing, supply chain and marketing across China and Europe.

Joerg: Obviously, the working methods and mentality are different between China and Europe. So, our colleagues needed to adjust and understand that working with our colleagues in China is different than working with European companies: we have different speed in in terms of posing questions and expecting answers. Just to give you one example: if you work with a European partner or customer, normally we would receive a complete list of questions from them, and we will answer the question list. The mentality or the working style in China seems to be rather: Questions will be rather provided one by one, and I want to get things out of the way quickly. Another interesting example would be, if something is of importance to a Chinese colleague, they would contact you by email, by WeChat, by telephone to ask the same question to underline the urgency. In Europe people tend to set expectations and deadlines: “please answer this question by tomorrow”. Only if the deadline has not been met you would follow up. So, if someone was new in the cooperation with the Chinese colleagues, it required some adjustment to the cultural differences.

Q: That’s good to know, and it is common to see culture shocks for most of the international projects. Speaking of the launch of Rivastigmine in China which is a milestone to Luye Pharma, does it also have the special significance to our German colleagues?

Joerg: Of course, we made it clear to everyone that this is a special business relationship other from our EU customers. By population, it's the biggest single market that we're conquering now - the Chinese market. It's our product in the Luye branding, and people are excited about it although it might be a little bit abstract so far because of the geographical distance. Once the packaging of the product become available, our people were immediately showcasing these samples for display in the entrance hall. Another sign of pride.

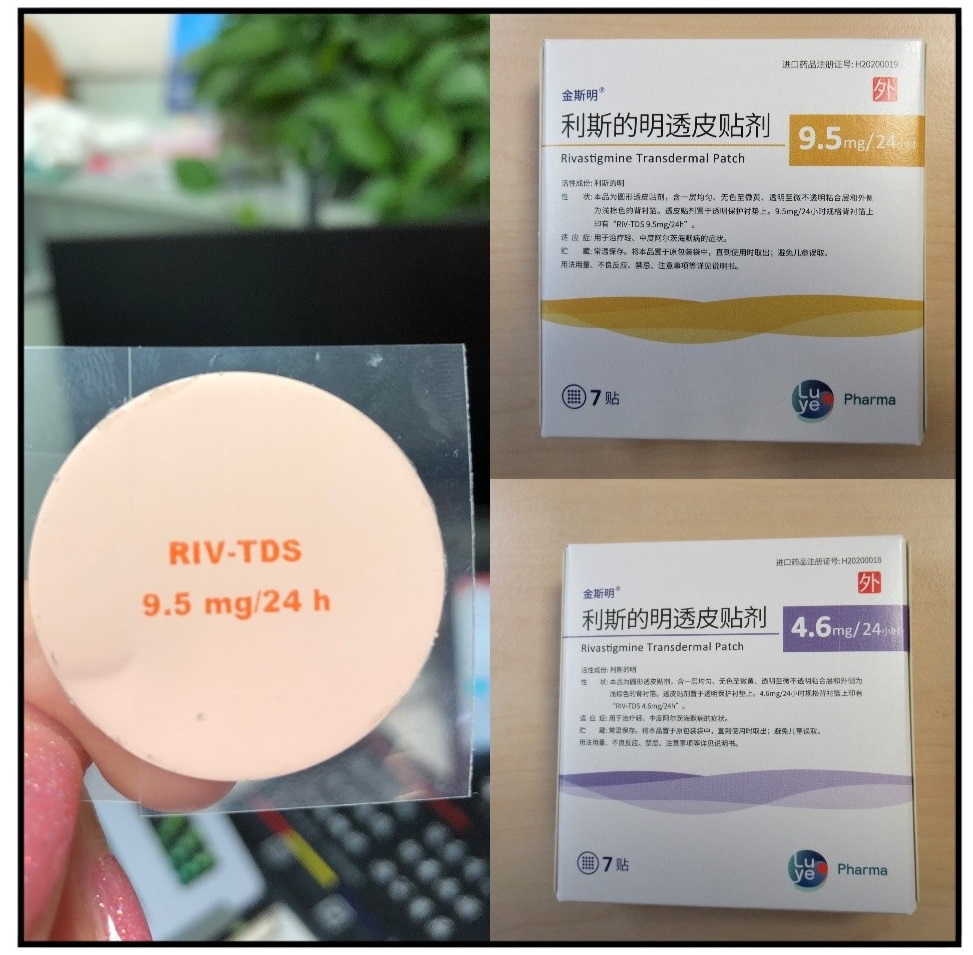

Product samples

I think it was also important very early in the process for the launch preparation that we presented material from our sales and marketing colleagues in China depicting the brand image and - although no one could read the texts of course - at least the images and the brand positioning were conveyed very well. So, the overall message became very clear to everyone when we see those marketing campaigns.

I think what we can still do to increase excitement would be that once the product hits the market to see further (pre-)marketing material, as we are not used to direct marketing so far. We're not used to do promotion, because we are in this business-to-business model, there's no Luye folding box in any European market up to now.

Q: What is your expectation to this project?

Joerg: My expectation and hope is that after the launch the product will perform well in the market we Luye Miesbach will receive a lot of additional orders. It's really a big chance, but we need to position the product quite well. I think that can be a big chance for the product. And for us, being manufacturer, it's always helpful to gain volume, to become even more efficient to ride the curve of economies of scale, which will in turn help to optimize the manufacturing cost.

Q: As you mentioned regarding your take away from this project. You mentioned about other patch products to be developed in the future, so what is your expectation on that?

Joerg: The first follow up to Rivastigmine single-day will be the rivastigmine multi-day patch. It will be a perfect life cycle product to Luye and probable fully exclusive to the market. Then what we will see will be the Buprenorphine patches, developed in Miesbach and Yantai and locally manufactured there. Once this product hits the market, of course, that will be another big milestone. Last but not at least we hope for the fertility control patch-Apleek also to conquer the Chinese market.

Q: Next one is quite a big question; how do we cope with the new normal in the time of COVID-19 pandemic based on your experience with this project?

Joerg: I think at least for the time being until we have a vaccine or something else to protect mankind, we will need to be careful. And we need to be sensitive and physically distant where we can. New work styles will establish, people working remotely, not everybody needs to be physically present in their offices. I think that is something that will change the overall style interaction between humans. I guess, now that everybody is getting used to those circumstances and as long as everybody stays healthy, I think we can cope with the overall situation and run the business.

Q: What about from the business perspective?

Joerg: Yeah, I think what we have seen during this year is the things turn out to be a little bit slower. We signed a lot of new customer contracts this year, so this was a really successful year, but you would expect a contract to take about 3 months to be negotiated and signed. This year it took easily rather 6 months, 9 months or even 12 months.

That shows there’s impact everywhere. And people don't sit in one room anymore, so you cannot go visit your customer for a negotiation session or signing ceremony. Another example are raw material supplies: they're pretty much back to normal after a period when our suppliers had to close factories, for example suppliers in Spain. Spain was hit very hard during the first wave, they had a complete lockdown, there were no factories operating, the transportation and logistics network broke down. No one was allowed to travel or to commute to work, and that's traumatic for an economy. We needed to react and take the right measures, make sure that our safety stock levels increased to address these supply risks.

Now we're back to normal looking at higher stock level as you need to have calculate longer lead times for transportation and logistics. All in all, everybody wants to make business. So everybody gets a little bit more creative. And that's the new normal. We need to be more flexible and agile. The best example would be that we're doing a video conference right now and if I can do it with you, I can also do it with a colleague who normally sits next door. So working from home doesn't really change anything either in the cooperation. It's just a mental question.

Q: So the last question is about Christmas because it's coming soon. And we know this is also the 4th year anniversary of Luye Germany. Any best wishes to the project team and all the colleagues of Luye?

Joerg: Yes. The simple fact is that we're doing this interview is underlining that we became an integral part of the Luye family. I think now increasingly with those multinational projects, more and more colleagues are getting exposure and that's very positive. I think we have accomplished a lot, especially with this highlight towards to year-end of the delivery of the launch quantities for rivastigmine. We thank everybody involved. Everybody involved has done a great job and it's the marketing guys in China who I have never met, who created the brand experience. They are very important to the project. We wish all the best for a very successful launch. Merry Christmas!

Q: Thank you for taking this interview, Merry Christmas to you too.

Afterword:

2020 is a special year with unforgettable memories. We selected Rivastigmine project as the topic of December staff interview, which represents a successful ending of this year. The market approval of Rivastigmine single-day patch does not only embody a milestone success to Luye Pharma, it has also improved the review and approval process in China. Center for Drug Evaluation of NMPA released Transdermal Patch Guidelines for Comments based on their review experiences with Rivastigmine single-day patch. Looking forward to the year of 2021, more and more Luye staff will march ahead with firm will, and achieve continuous progress.